Not known Details About 24hr Media

Not known Details About 24hr Media

Blog Article

Everything about 24hr Media

Table of ContentsGetting The 24hr Media To WorkHow 24hr Media can Save You Time, Stress, and Money.Not known Facts About 24hr Media24hr Media Can Be Fun For EveryoneThe Only Guide for 24hr Media

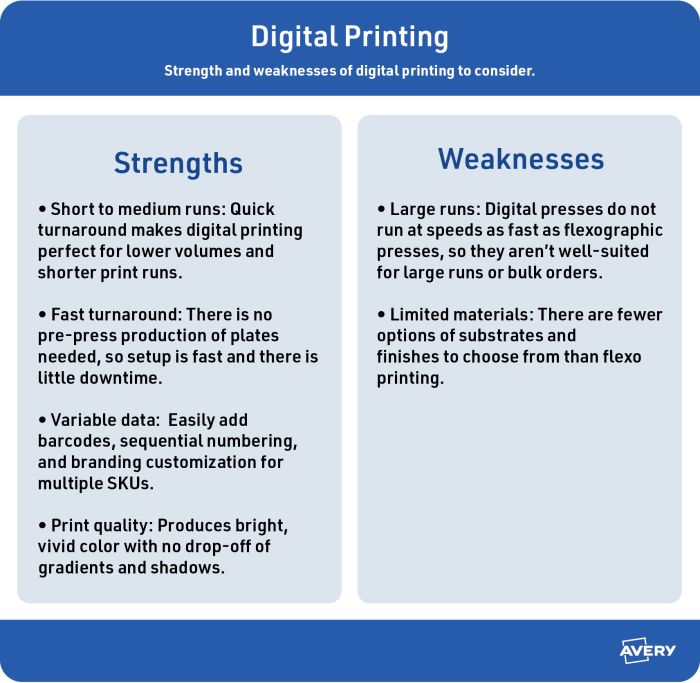

Offset, gravure printing and flexography are the most usual kinds of traditional printing in the packaging space and each includes moving the photo from a plate to the surface area. To do this, initially the plate needs to be developed, and it is the production of these plates that take some time, and cost cash.According to PMMI, electronic printing allows brand names and makers to respond quickly to client demands while improving the supply chain, lowering warehousing price and waste, and enjoying faster time to market. That all noises terrific, but just how does this technology do all that? The major differentiator of these modern technologies is that there are no set-up charges and no plates with electronic printing.

According to Wikipedia, the biggest distinction in between electronic printing and standard approaches such as lithography, flexography, gravure, or letterpress is that there is no need to change printing plates in electronic printing, whereas in these analog printing techniques the plates are repeatedly changed. This leads to quicker turn-around time and lowers price when using electronic printing.

Digital printing is extremely adaptable, so it's easy to make modifications to the package style promptly. It all goes back to the plates.

The Best Strategy To Use For 24hr Media

Much more stock can indicate even more waste down the roadway. With standard printing approaches, short-run printing is simply not possible. Since a fantastic style can make or damage your item, electronic printing constantly develops high-quality, clear and colorful graphics each time. Digital printing on flexible pouches adds the bright, dynamic, and exact graphics that virtually beckon consumers to connect and touch them.

Packing ... Are you familiar with the benefits of electronic printing? Both balanced out and digital printing have their area in the printing sector.

In this article, we will discuss the advantages of electronic printing to aid you much better comprehend if digital printing is simply what you require. Basically - electronic printing prints material straight onto the paper. It eliminates some actions required in offset printing, like developing steel plates. Inkjet printers use small nozzles to spray beads of ink onto the substratum.

Top Guidelines Of 24hr Media

As digital printing constantly develops, it supplies much more opportunities and greater output high quality daily. Sometimes, the print top quality can be as high as to offset printing. As years pass, digital print is becoming extra available, with enhanced rate and quality. This is just the reason printing business are adding digital printing to their offer.

For balanced out printing, if any type of error goes unnoticed prior to producing home plates, there will certainly be a high expense of producing a brand-new one. Yet, with electronic printing, this is not the instance. Everyone always hopes there will be no mistakes, knowing the price of remedying them if they happen is always a good idea.

This implies every single item will look the same, so the opportunity you will require to discard any one of them due to the fact that of variances is low. Additionally, considering that a proofing sample is printed on the very same maker as the click here for info item itself, color proofing is really precise. Any troubles with color will certainly be noticeable on the proof, and therefore it will be possible to alter it prior to publishing the entire run.

The Main Principles Of 24hr Media

Digital printing, on the various other hand, needs minimal configuration. This is terrific when you are in a rush to get your printed products.

This indicates more demands for electronic on-demand print manufacturing. Every consumer values a personalized message. One of the advantages of digital printing is that tailoring your marketing materials could not be easier. Economical, smaller sized sets enable businesses to tailor each order. Have a back-to-school sale? Make a flyer to target parents and one more one to target the trainees.

Digital printing is the ideal selection for variable data printing, like customized codes and addresses on direct-mail advertising. With digital printing, it is much less troublesome to make last-minute adjustments to your design. Often the most effective type of interaction is not digital. In these situations, relying upon electronic printing can ensure these orders have a marginal ecological influence.

The Ultimate Guide To 24hr Media

There is additionally no need to cleanse the plates after printing. The advantages of digital printing consist of that there is no waste from extra or remaining ink, paper, or chemicals because only what's needed obtains published. - for extremely brief runs, electronic printing is the method to go, without a doubt.

Gone are the days of intricate configurations and long turnaround times - electronic printing has actually revolutionised the print market. The printing globe has come a lengthy means considering that the days of Gutenberg's printing machine. The new typical is structured processes and cost-effective remedies for publishing onto practically anything you can consider.

Report this page